LEVEL GAUGES

Reflex Level Gauge

Reflex Level Gages are ideal for clean total level indication applications for refining, petrochemical and general use applications. The reflex prisms are molded and polished to provide a crisp black-silver bi-color indication of the fluid level. As light passes into the reflex glass, if there is fluid present, the light continues through the glass and reflects off the back of the level gage, providing a black color for fluid level regardless of the actual color properties of the process fluid. If fluid is not present, the light is reflected off the glass back towards the user, providing a shiny silver or mirror-like appearance to indicate vapor space.

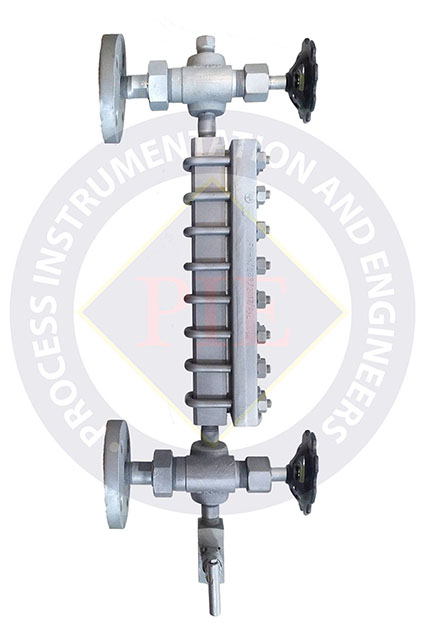

Transparent Level Gauge

Transparent Level Gages are selected for interface level indication, dirty service or any application that requires the use of a shield to protect the glass from corrosion. A transparent gage is also known as a "thru-vision" gage since the gage is constructed with two pieces of flat polished glass assembled on opposite sides of the level gage chamber. Since the user can see straight through the gage, it is also easy to view the fluid properties, such as color, whereas this would not be possible with a reflex gage. The use of an illuminator is always recommended on a transparent gauge.

Tubular Level Gauge

Tubular Level Gauge is fitted between two end connections through gland packings. The gauge is mounted parallel to tank such that the tank liquid seeks its level in the gauge.

Guards are provided in the form of tie-rods / c-channels around the gauge to protect it from accidental blows and also to prevent liquid splash in case of glass break. End connections have built-in isolating valve, drain valve & vent plug. Glass removal / replacement is possible without dismantling of gauge.

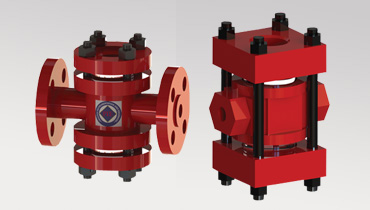

Tubular_Level_GaugeSight Flow Indicators

Sight Flow Indicators provide an effective way to view the condition of liquids or solids flowing through pipelines at almost any flow, pressure, or temperature. PIE Sight Flow Indicators assure a direct & positive indication of flow direction & condition of the medium being transported. They also indicate any blockage in the pipe section due to dirt, sediments or corrosion.

PRODUCT CATALOG OF SIGHT FLOW INDICATORSGauge Valves

PIE Gauge valves are designed to fit PIE series of Level Gauges. Made of sturdy constructions, these provide long life service.

Union connection enables removing of gauge glass without removing the valve. Also features like back seating stem ensure safety in the event of glass failure.

PRODUCT CATALOG OF GAUGE VALVESCalibration Jar

PIE also manufactures Calibration Jars for calibration of pumps. These provide an accurate pump calibration of higher pump flow rates. The jar is installed between the suction side of the pump and the tank. The flow rate of the pump is checked by closing the valve between the tank and the jar and observing the level change in the jar for one minute.

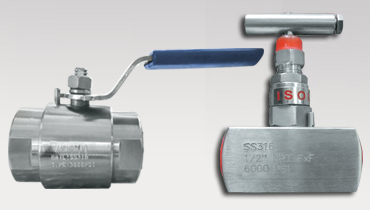

PRODUCT CATALOG OF CALIBRATION JARNeedle Valves and Ball Valves

PIE needle valves are for use in system instrumentation applications to isolate or vent system media. The hardened stainless steel, non rotating needle promotes leak-tight shutoff and long service life. The valve stem threads are isolated from the media.

- Straight and angle patterns.

- Compact design.

- Stainless steel stop pin.

- Stem threads above packing, protected from system media.

- Non rotating, hardened needle design for leak-tight shutoff and long service life.

- Safety back-seating needle design seals in fully open position.

- Suitable for sour gas service; materials are selected in accordance with NACE MR0175/ISO 15156.

Hammer Unions

We offer a full line of union swivel connections to fit a variety of applications. Hammer unions come in N.P.T. threaded-style and welded-style and are made of heavy duty steel for tough and long lasting use. Hammer unions can also be treated for use with sour gas H2S service upon request. (Sour Service Models according to NACE MR-01-75)

PRODUCT CATALOG OF HAMMER UNIONSAlpha Magnetic Level Indicator

The advantage of magnetic level indicator technology is total isolation of the process within a sealed piping column. This eliminates the risk arising our of leaking seals, clouded glasses, and broken glass tubing. Easy access to cleaning and adaptation to a variety of mounting styles and process connections makes MLI preferable over glass level gauges.

Magnetic Level IndicatorInstrument Cages / Chambers

PIE also manufactures Instrument Cages and chambers for mounting of external sensing instruments such as Level switches, Ultrasonic or Radar Level Gauges etc. The cages are designed and manufactured as per ASME B31.3 standard, and is Pressure Equipment Directive (PED) complaint. Weld neck flanges and full penetration welding in accordance with EN ISO 15614-1:2004 and ASME Boiler and pressure Vessel Code Section 1X are used throughout. Standard materials: ASTM A-106 Grade B// SS316// SS316L. Special exotic material is available on request. Our cages and chambers are accompanied with complete Material Test Certificates and Hydro-test certificates according to Customer’s requirement.

Instrument Cages